Steam trap

What is a Condensate Trap? Working Principle, Types and Industrial Importance — ORFA Industrial

The efficient operation of steam systems depends on the correct functioning of condensate traps. In this article, we have created a detailed technical guide, with ORFA Industrial expertise, explaining what a condensate trap is, its operating principles, types, and industrial applications.

What is a condensate trap?

A condensate trap is a control element in steam systems that automatically discharges the water (condensate) that forms and keeps the steam in the line. Its function is to remove condensate, trap steam, and remove air and other gases from the system. This improves heat transfer, reduces energy losses, and protects equipment.

How does a condensate trap work?

Although each condensate trap operates with a different mechanism, the basic principle is the same: prevent vapor from passing through and discharge condensate.

- Float-type condensate trap: When condensate increases, the float rises and the drain opens. It is the most efficient solution in heat exchangers.

- Thermodynamic Condensate Trap: The disc closes due to the difference in steam velocity and density. It is resistant to high pressures.

- Bimetallic Condensate Trap: Operates with a temperature-sensitive bimetal structure. Ideal for demanding processes.

- Thermostatic condensate trap: Opens in cold weather and closes in hot weather. It is the type that removes air from the system most quickly.

- Inverted Bucket Condensate Trap: Offers reliable operation in contaminated lines.

Types of Condensate Traps

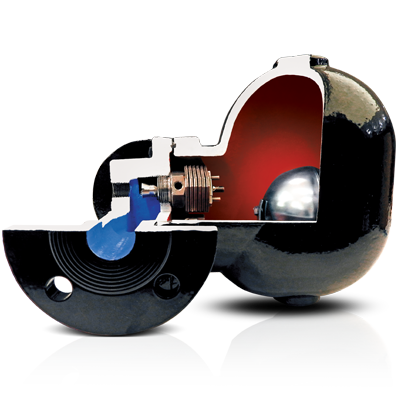

1) Float-type Condensate Traps

The float rises with the condensate and opens the drain.

When steam arrives, the float drops and closes.

✔ Provides continuous flow

✔ It is the most efficient type of heat exchanger.

It ensures continuous and balanced condensate discharge. This heat exchanger is the most preferred type in steam heating lines. It has the advantages of high capacity, low pressure loss, and quiet operation.

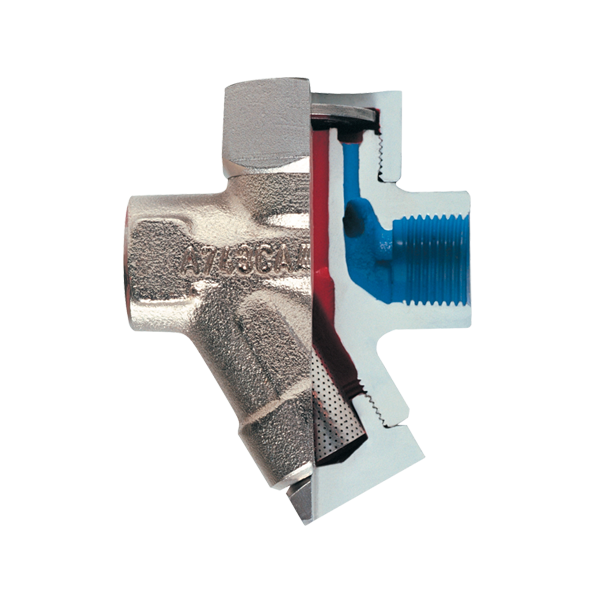

2) Thermodynamic Condensate Traps

The difference in speed and density of the steam pushes the disc upwards.

The disk opens when condensation returns.

✔ Compact design

✔ High pressure resistance

It has a compact design and delivers excellent performance in high-pressure applications such as outdoor, petrochemical, and refinery settings.

3) Bimetallic Condensate Traps

The bimetal disc bends due to the change in temperature.

It opens in the cold and closes in the heat.

✔ High temperature resistance

✔ Reliable in challenging conditions

Thanks to its temperature-sensitive metal structure, it operates stably over a wide temperature range. It is resistant to high temperatures and pressures.

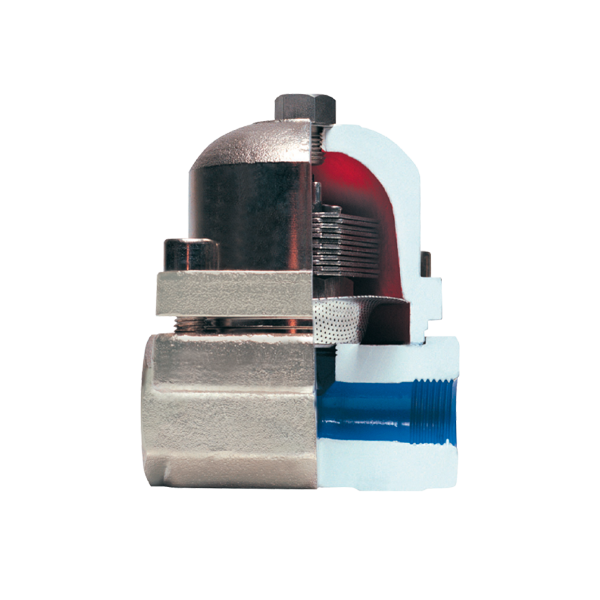

4) Thermostatic Condensate Traps

The thermostatic capsule opens when the temperature drops.

✔ The type with the best air ventilation.

✔ It quickly expels air from the system initially.

It is the type of condensate trap with the highest air venting performance. It is preferred in processes with high initial loads.

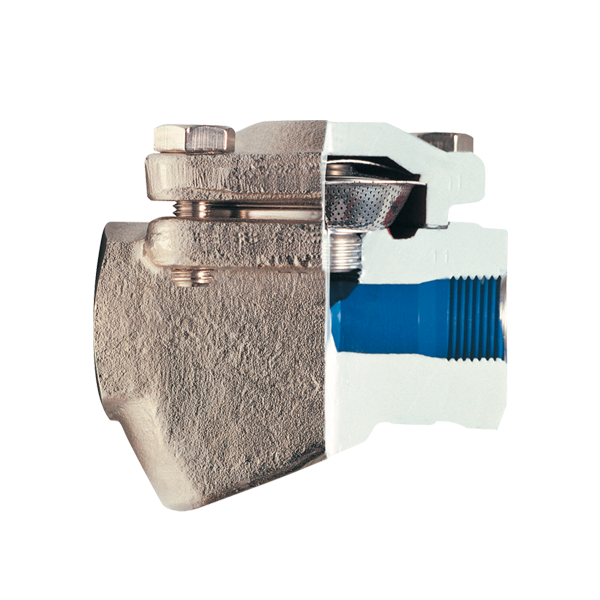

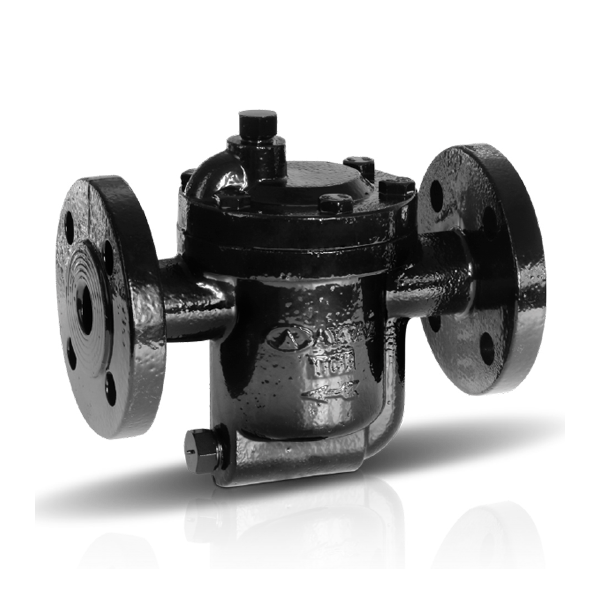

5) Inverted Bucket Condensate Traps

The steam lifts the bucket and closes; it opens when condensation comes out.

✔ Ideal for dirty and challenging processes.

It operates smoothly in lines containing dirty condensate. It is resistant to shocks and pressure changes.

Applications of Condensate Traps

- Steam distribution lines

- Plate and tube heat exchanger systems

- Heating and steam process lines

- Food, chemical, textile processes

- Autoclave, boiler, jacketed tank applications.

- Steam separator discharge

The Importance of Choosing the Right Condensate Trap

Incorrect steam trap selection;

✘ 20–30% energy loss

✘ Heat exchanger inefficiency

✘ Water hammer risk

✘ Increased maintenance costs

✘ Decrease in steam quality

This leads to serious consequences.

Incorrect steam trap selection can lead to energy loss, hammering, poor heat transfer, and line failures.

The right choice is:

- It saves energy.

- It guarantees the system operates securely.

- It extends the lifespan of the equipment.

- It increases the efficiency of the steam line.

Digital Monitoring Systems in Condensate Traps

✔ It indicates leakage and malfunction status via LED or digital display.

✔ Suitable for PLC integration.

✔ Minimizes energy losses

In modern facilities, leaks and malfunctions can be detected instantly using condensate trap monitoring devices. These systems can have LED displays or PLC integration, minimizing energy losses.

Conclusion

Condensate traps are critical for the efficiency, operating costs, and safety of steam systems.

ORFA offers solutions ranging from float-type to thermodynamic, thermostatic, and bimetallic models, providing options suitable for all types of industrial processes.

At ORFA Industrial, we offer our customers:

Choosing the right product,

Technical consultancy,

Condensate trap inspection service

We offer professional support on these topics.

Condensate traps are an invisible but crucial component of steam systems. Properly selected, correctly installed, and regularly inspected condensate traps provide businesses with high energy efficiency, safety, and a long equipment lifespan. At ORFA Industrial, we continue to offer suitable condensate trap solutions for every process.