Ayvaz Rod Level Switch AU-20YD

%62 Discounted Product

0 - Comment / Read Comments

645,71 USD

245,37 USD

Category

Brand

Stock Code

704950000102

Price

538,09 USD + VAT

* Installments starting from 245,37 USD!

You can send us any questions you have about technical support, product information, or general topics. Our experts will get back to you as soon as possible.

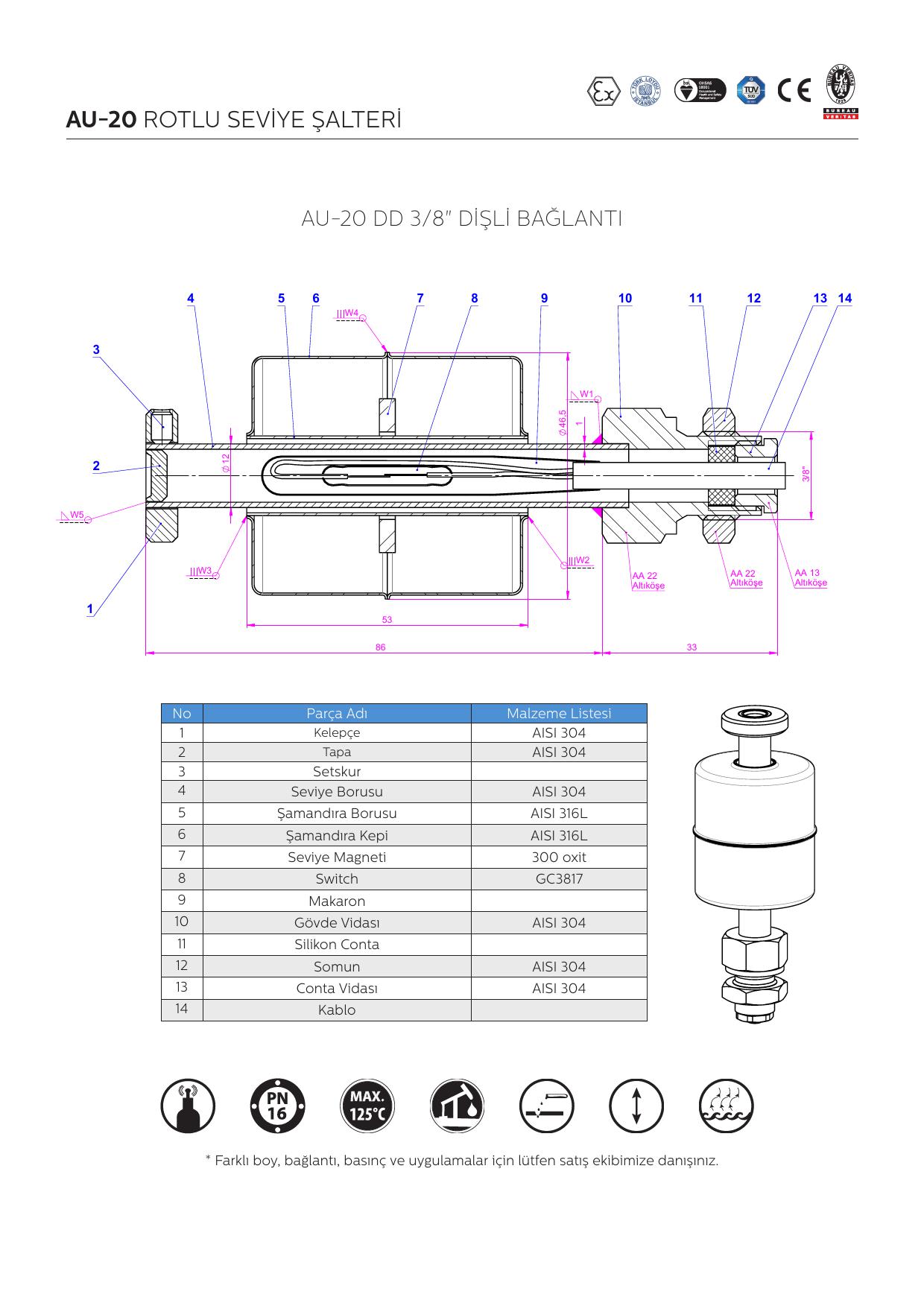

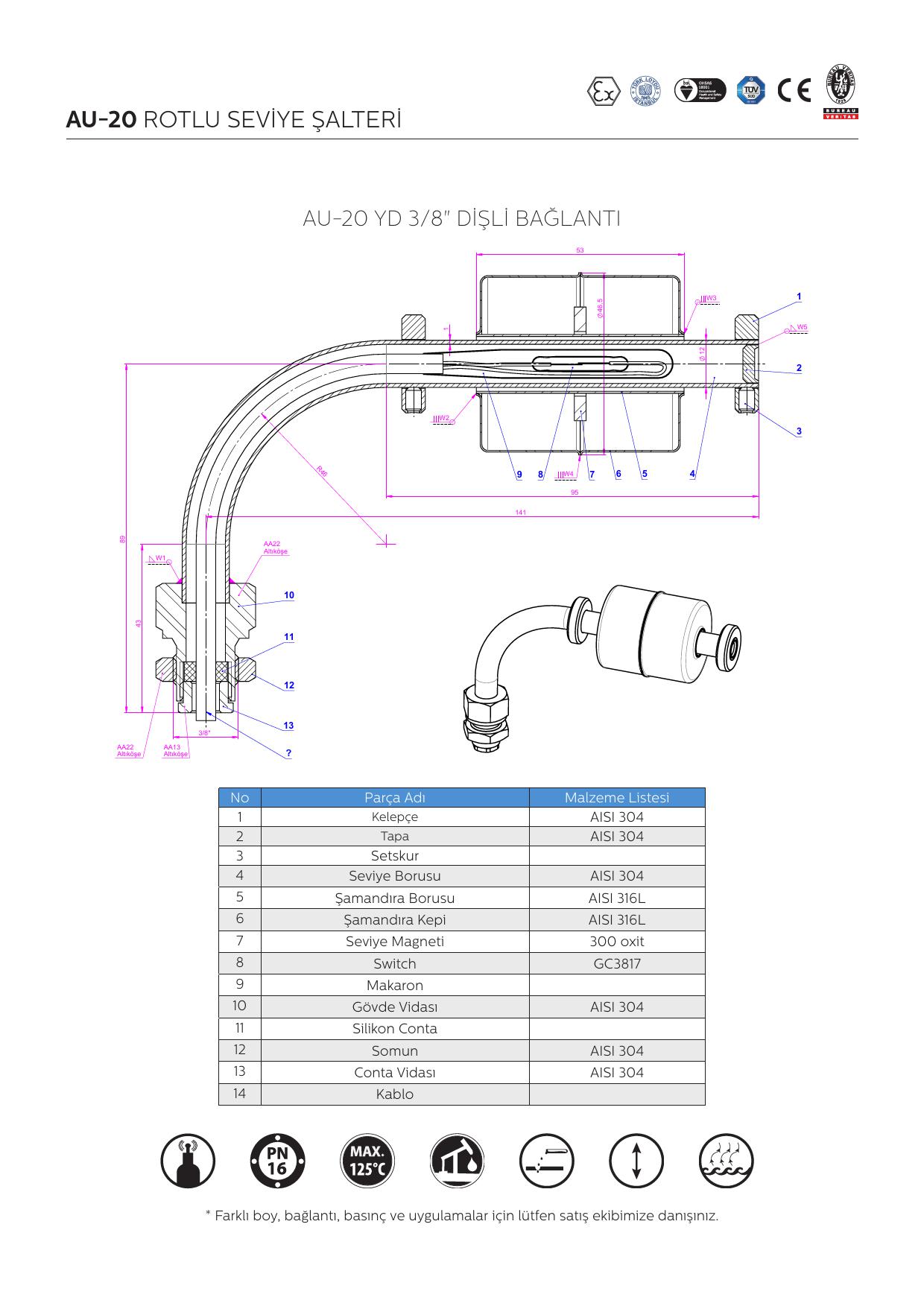

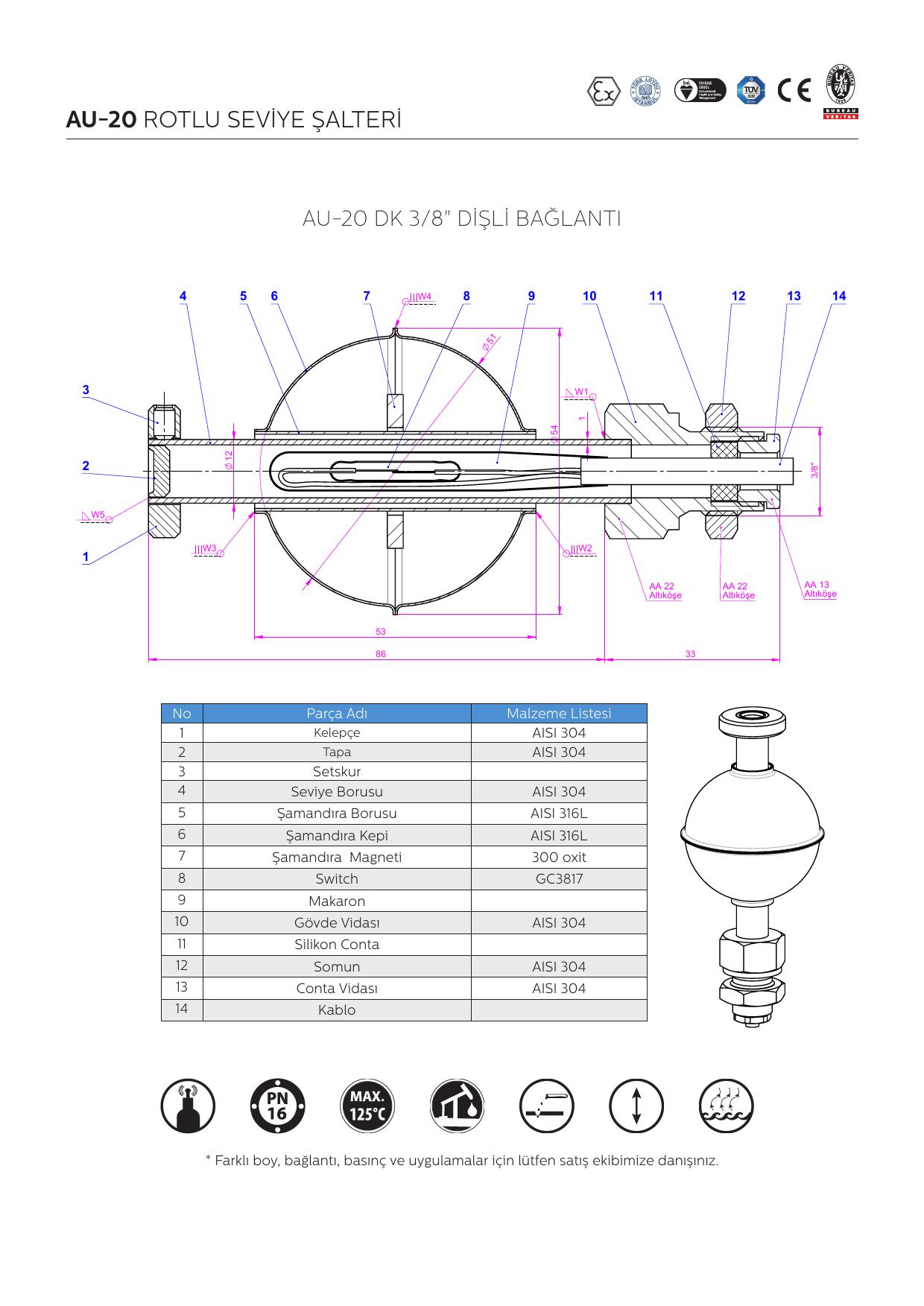

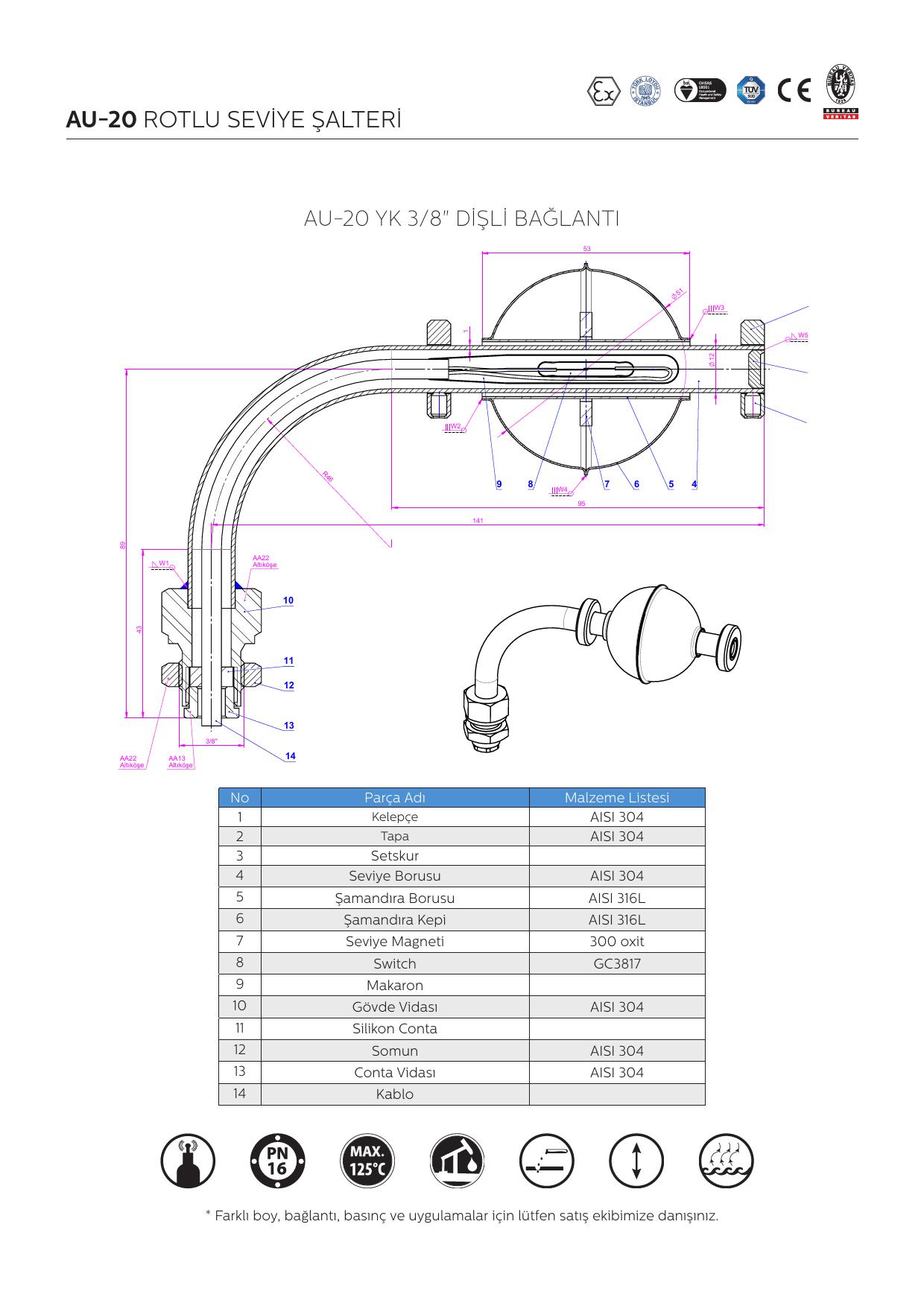

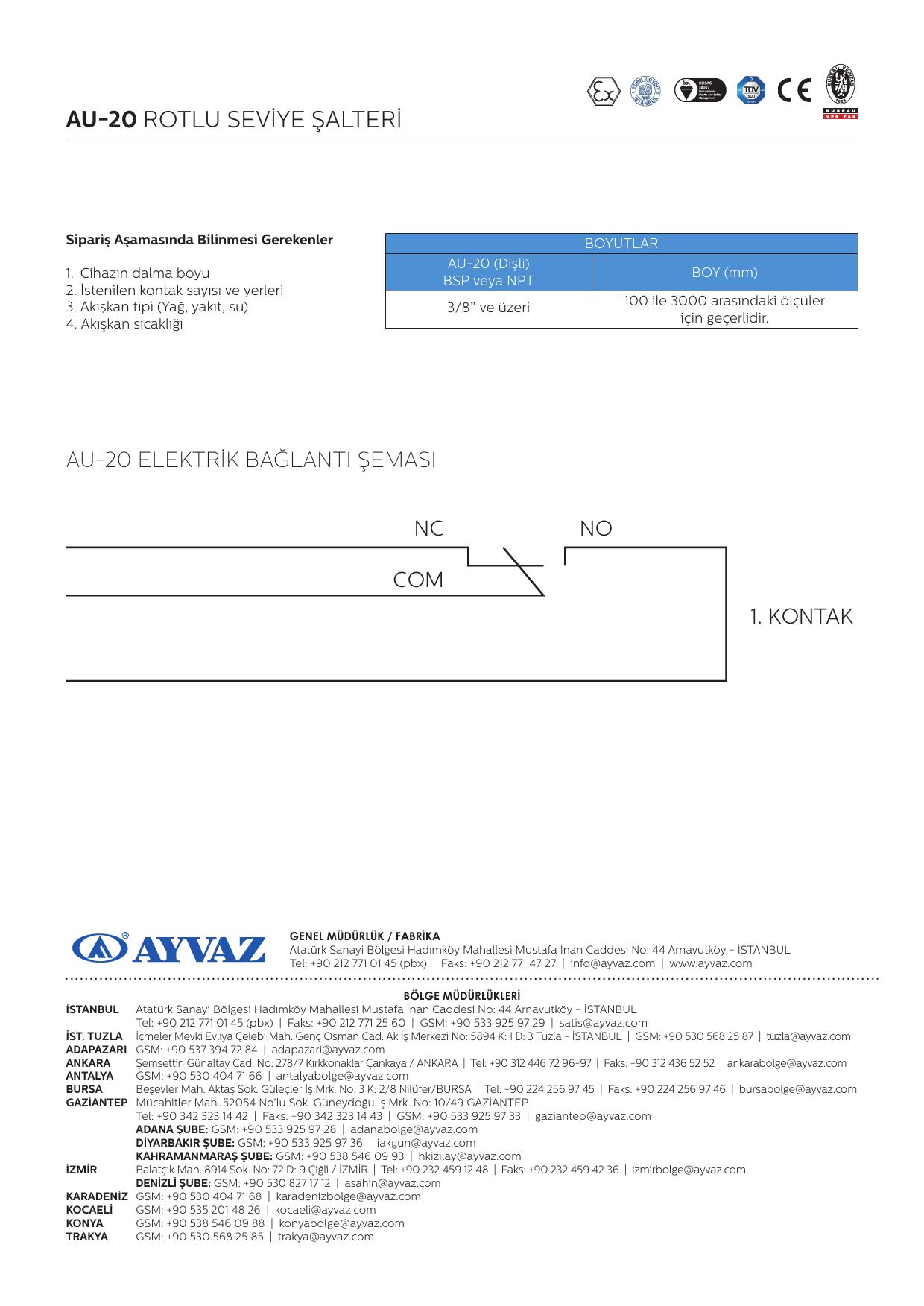

AU-20YD Rod Level Switch

The Ayvaz AU-20 Rod Level Switch, which we sell as ORFA Industrial Products Industry and Trade Inc., is designed for reliable and precise liquid level control in all types of vessels, whether pressurized or non-pressurized. This device utilizes a control element consisting of a stainless steel float and a magnetic reed switch circuit housed in a stainless steel tube.

Thanks to the buoyancy of the liquid, the float moves linearly up and down the tube. When the magnet inside the float and the reed switch approach each other, they create contact, opening or closing the circuit. This feature makes it safe for use in on/off applications such as controlling fluid level.

Operation and contact points can be configured to suit user needs. The minimum spacing between contacts, which can be configured as normally open or normally closed, is 30 mm. The contact point provides dry contact when the float reaches the specified level.

Product Advantages:

High Performance: Providing reliable contact at a single point in low-height tanks.

Flexibility: Flexible use with normally open or closed contact options.

Durability: Long service life and durability with complete stainless steel parts.

Easy Installation: Ease of use with horizontal or vertical installation options.

Technical Specifications:

Pipe and Float Material : AISI 304 Stainless Steel

Connection: 3/8” Threaded

Operating Temperature: -10 / +125 ºC

Switch Voltage (Max.): 400 VAC / DC

Contact Type: Normally Open

Minimum Density: 0.80 gr/cm³

Maximum Working Pressure: 16 bar

Switch Capacity: 60VA

Switch Current: 1.0VA

Mounting Type: Horizontal or Vertical

Cable Connection: 2 x 0.25 mm²

Protection Class: IP68 + EX-PROOF

Rod Level Switch - Working Principle

Basic Working Mechanism

Float and Tube: The Ayvaz AU-20 Rod Level Switch consists of a stainless steel tube with a stainless steel float that moves inside. This tube is mounted vertically in the liquid, and the float moves up and down the tube.

Magnetic Field and Reed Switch: The float contains a powerful magnet. This magnet approaches a reed switch (magnetic switch) located within the tube, creating a magnetic field. The reed switch is activated or deactivated by this magnetic field. Reed switches are usually located at specific points in the tube, and when the float reaches these points, they either complete or break the circuit.

Operation Steps

Liquid Level Change : As the liquid level in the tank or container changes, the float moves up or down in the tube due to the buoyancy force of the liquid.

Effect of Magnetic Field: As the float moves up or down, the magnet inside it also moves. This movement causes the magnet to move closer to or further away from the reed switch.

Reed Switch Response: When the magnet inside the float approaches the reed switch, the contacts inside the reed switch close or open. This indicates that the liquid level has reached a certain point. The minimum distance between the contacts can be set to 30 mm.

Electrical Output: The opening or closing of a reed switch generates an electrical signal. This signal is transmitted to the level control system, enabling liquid level monitoring. This signal can be evaluated by control systems, which can then activate devices such as pumps, valves, or alarm systems.

Customizable Operating Modes

Normally Open/Closed Contact: The reed switch circuit can be configured as either normally open (NO) or normally closed (NC). This allows the user to determine the device's operation based on their needs.

Minimum Density: The device is designed to operate with liquids with a minimum density of 0.80 g/cm³. This increases its usability in a wide range of applications.

Application Areas:

Shipbuilding Industry: Reliable level control in tanks used in ship construction and maintenance.

Waste Water and Bilge Tanks: Level control in waste water and bilge tanks.

Waste / Clean Water Tanks: Precise level control in various water tanks.

Food Industry: Hygienic and safe level control in food production facilities.

Fuel Tanks : Reliable level control in fuel storage tanks.

Acid Tanks: Reliable use in acid tanks requiring chemical resistance.

Condensate Tanks: Level control in condensate tanks in steam systems.

Chemical/Petrochemical Tanks: Reliable level control in chemical and petrochemical processes.

Be the first to comment on this product!

No questions have been asked about this product yet.